Client is a Major Defense Prime and Global Aircraft OEM

Client is an Aircraft OEM in a multi-site and matrix environment with customers in over 70 nations.

- Supplier Quality oversight of 685 suppliers in 14 countries and Billions in direct spend

- 25,000 + employees worldwide

- Fortune 50 company

“Finding supplier defects via inspection and reacting to defects via corrective action is no longer good enough. We need to take proactive action today to prevent the defects of tomorrow”

The Challenge

Over the prior 12-24 months, the client had worked with Unitek to augment their product verification activities by stationing contract Supplier Quality Engineers (SQE’s) on-site at supplier facilities.

The client saw significant reduction in supplier defects as these contract SQE’s reacted swiftly to supplier defects by working product-specific containment and corrective action.

With a good program in place to react to defects, the client wanted to utilize this existing infrastructure of contract SQE’s to prevent defects before they occur.

“Supplier defects cause a significant disruption to our programs and our business” said the Enterprise Supplier Quality Program Leader.

“Reacting swiftly to defects was once praiseworthy. But in today’s environment it simply isn’t good enough to find and resolve defects – we need to prevent them”.

“Our business, our customers, and the market demand zero defects [escapes] from suppliers. So we must ask ourselves – what proactive actions are we taking today to prevent the defects of tomorrow? This is the real work that lies ahead for us.”

Client Goals and Constraints

The client’s vision was to prevent the defects of tomorrow through:

- Proactive Supplier Surveillance

- Enhanced First Article Inspections (FAI)

- Proactive Supplier Development of Critical Processes

The client had utilized their own internal teams to develop the frameworks and processes required to implement their vision.

The Solution

The client tasked Unitek to execute their vision by using the network of contract SQE’s we already had in place across their supply base.

“We simply couldn’t afford the delay of implementation from hiring an army of SQE’s to go execute this body of work” said the Supplier Quality Program Manager.

“Leveraging Unitek’s network of contract SQE’s who were already in-place and familiar with our suppliers was a natural and logical fit”

Unitek worked with the client to develop an implementation plan that included:

- Defining performance expectations for the contract SQE’s

- Developing and deploying training to contract SQE’s

- Validating early implementation to ensure actual results met expectations

The Proactive Supplier Surveillance consisted of on-site assessments of suppliers’ critical processes. Where industry has traditionally taken a compliance-based approach with binary scoring (i.e. pass/fail), the client had developed a process maturity approach where results are scored on a sliding scale (i.e. 1-10) based on demonstrated process maturity.

Processes that scored below a certain threshold represented a high risk of future process failure and required the supplier to mature that process area. The numeric results could then be trended over time to validate improvements.

The contract SQE’s would:

- Coordinate directly with suppliers to schedule and perform the assessments

- Identify weaknesses, gaps, and risks in key process areas that are likely to cause future product impact

- Work directly with suppliers to close gaps and risks by maturing their processes

The Enhanced First Article (FAI) Inspections consisted of expanding the supplier AS9102 requirements for when a new and delta FAI was required, along with stronger criteria for when and how the client would sign off on a FAI as ‘approved’.

The client’s rationale for this was simple; they were not seeing 100% quality on post-FAI deliveries from their supply base and needed an enhanced approach that was capable of delivering that level of performance.

Under this new approach, FAI approvals would no longer be granted on a single ‘Golden Part’ but rather over multiple successive manufacturing lots, thus pushing suppliers to truly stabilize and mature their manufacturing processes to achieve predictable future performance.

The role of the contract SQE’s was to:

- Review supplier FAI’s on-site, including scheduling and approval with suppliers

- Validate suppliers’ manufacturing processes were stable and repeatable by reviewing first pass yield (FPY) and process capability (i.e. CpK) data, among others

- Identify and eliminate any special causes of variation in supplier’s manufacturing processes

- Approve the FAI only when objective evidence demonstrated a high confidence of achieving 100% quality on post-FAI deliveries. In the interim, product may continue to ship provided it had been adequately inspected and found to be defect-free.

The outputs of all the above activities were translated into Proactive Supplier Development actions taken at suppliers.

At first, the contract SQE’s would have to wait to be tasked by the client on how to respond. After a learning period, the client became comfortable with the approach and procedures were developed, training was provided, and the contract SQE’s began operating completely autonomously in accordance with their training.

The contract SQE’s would:

- Maintain a task register of quality issues, gaps, risks, and tasks they were working at their assigned supplier. This was done in a centralized software platform where the client could monitor tasks and deadlines for any contract SQE or supplier

- Work directly with the supplier’s leadership to provide voice of the customer and support the development of action plans to address the items

- Monitor implementation of suppliers action plans, including holding them accountable for slippages and escalating when necessary

- Validate improvements through planned and minimally intrusive follow-up assessments

The Outcome and Results

Through these initiatives, the contract SQE’s were proactively identifying and resolving supplier quality issues at their assigned suppliers before the issues could result in product impact (i.e. escapes, disclosures, delays.)

Unitek implemented these initiatives on-time and on-budget. Additionally, the contract SQE’s maintained a > 95% on-time rate for the execution of their daily work.

“We didn’t just want warm bodies – we needed ownership, execution, and results!” said the Supplier Quality Program Manager. “Unitek executed fantastically on all fronts.”

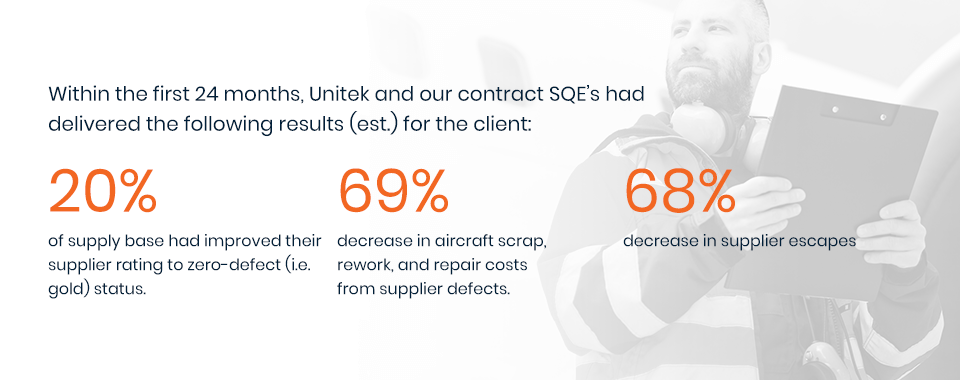

Within the first 24 months, Unitek and our contract SQE’s had delivered the following results (est.) for the client:

- 20% of supply base had improved their supplier rating to zero-defect (i.e. gold) status

- 68% decrease in supplier escapes

- 69% decrease in aircraft scrap, rework, and repair costs from supplier defects

These improvements in supplier quality had cascading benefits for the client, such as:

- Improved supplier cost and delivery performance

- Improved aircraft manufacturing operations with less disruptions and out-of-station work due to supplier defects

- Improved program execution and customer confidence

“We could really see and feel the improvement!” said the Supplier Quality Program Manager.

“The production line was flowing much better, the Earned Value metrics were improving, and the nature of the work for our SQE’s had made a palpable shift from fire-fighting to fire-prevention. That’s precisely where we wanted to be!”

What’s Next For The Client

The client was able to utilize Unitek contract SQE’s to prevent future supplier defects with fantastic results!

Consequently, a fast-growing portion of the client’s supply base is being granted inspection delegation. While this trend brings many benefits for the client, they find that issuing and managing these delegations represents a technical and administrative burden which ties up resources that could be utilized elsewhere in the organization.

A potential next step in the client’s journey is implementation of Unitek’s Supplier Funded Program. Under this program offered to the Aerospace & Defense industry, Unitek manages the Designated Supplier Quality Representative (DSQR) self-release program for the client while holding suppliers contractually, financially, and behaviorally accountable for their own cost of poor quality (CoPQ).

Find out more

NTS Unitek offers an ever expanding range of global supplier quality, supply chain management and technical support services across North America and Europe. all our services are scalable, designed to expand and contract based on the complexity, rate of growth, and volatility of your supply chain.

Contact us

Unitek Technical Services, Inc.

5900 Fort Drive

Suite 100

Centreville, VA 20121

Tel: +1 (800) 998-9395

To find out how:

Go to www.nts-unitek.com/contact-us

Or call us at +1 (800) 998-9395